Anion Exchange Membrane (AEM) Electrolysis:

Discover our AEM Electrolyzers, designed to deliver the flexibility and efficiency needed for your renewable energy projects. Like alkaline electrolyzers, they don’t rely on costly metals, reducing your investment costs. At the same time, they emulate PEM technology’s ability to seamlessly adapt to fluctuating power output from wind and solar sources. Perfectly suited for your energy transition, our AEM Electrolyzers are the versatile solution for a sustainable future..

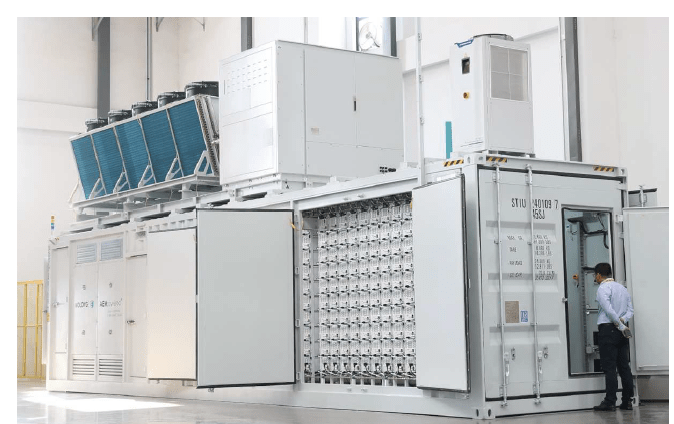

AEM technology, which is fully developed, proven, and ready for widespread market deployment and integration in a wide variety of projects that demand low Green Hydrogen from renewable energy sources.

Why AEM ?

Anion Exchange Membrane (AEM) Electrolysis:

AEM electrolysis is a water-splitting technology used to produce hydrogen. Unlike proton exchange membrane (PEM) electrolysis, it utilizes a semipermeable anion exchange membrane that conducts anions to decompose water into hydrogen and oxygen.

Advantages of AEM Electrolysis:

- Cost-Effective Catalysts: AEM electrolysis does not require expensive noble metal catalysts, utilizing more affordable transition metal catalysts instead.

- Alkaline Environment: Like alkaline water electrolysis, AEM operates well in an alkaline medium.

- Lower Water Purity Requirements: Compared to PEM, AEM electrolysis can use a slightly alkaline solution, which reduces handling issues and the risk of leakage associated with highly alkaline solutions.

- Flexible Operation: Designed to accommodate variable power inputs from renewable sources, maintaining stable hydrogen production despite fluctuations in electricity supply Up to 35 bar.

- Flexible Operation: Designed to accommodate variable power inputs from renewable sources, maintaining stable hydrogen production despite fluctuations in electricity supply Up to 35 bar.

- Cost-Optimized Design: Utilizes non-precious metal catalysts, minimizing capital expenditure without compromising performance.

- Modular Scalability: The system’s modular architecture allows for phased capacity expansion, adapting to evolving project requirements.

- Integrated Balance of Plant (BoP): The Integrated BoP includes advanced rectifiers, safety, and thermal systems to boost performance and reliability. An optimized plant layout at larger sizes reduces CAPEX, enhancing cost efficiency and safety

- High-Purity Hydrogen Output: Delivers hydrogen with a purity of up to 99.95% (99.999% with optional dryer).

- Rapid response times enable hot startup from 0 to 100% output in as little as 135 seconds; optimizing turn-over times for large BOP integration.

- Specific Power Consumption: 4.61 kWh/Nm3H2 (51.3 kWh/kgH2).

News

latest news and topics of Interest

-

JOHANESBURG April 2025 Innovative Green Ammonia Project: Transforming Mining Wastewater into a Sustainable Energy Carrier

Innovative Green Ammonia Project: Transforming Mining Wastewater into a Sustainable Energy Carrier In a groundbreaking move towards sustainable mining and waste management, a consortium of leading companies has embarked on an ambitious project to…

-

8th April 2025 – Hy-ON Production Team Visits Hydrogen Terminal Project at Braunschweig Research Airport

The Hy-ON Production Team recently conducted an on-site fact-finding mission at the Hydrogen Terminal project located at the Braunschweig Research Airport. Spanning 4,700 square meters, this innovative facility serves as a hub for hydrogen…

-

DAVOS January 2025 World Economic Forum 2025

During the World Economic Forum (WEF) 2025 in Davos, we once again engaged with critical industry stakeholders to strengthen our collaborative efforts. Hy-ON had the opportunity to participate in the prestigious Fortescue roundtable event,…

-

Green Hydrogen Summate

The new partnership between GeFP and Hy-ON represents a significant development in the E-Fuel space, focusing on the production of Green Methanol in South Africa. This project, aiming to produce 800,000 tons of Green…

-

December 2023 GeFP Green eFuel Methanol Corridor

Pioneering Green Methanol Production in Gauteng: The GeFP and Hy-ON Collaboration in Technology Consortium As sustainability and renewable energy take center stage worldwide, innovative projects are emerging to address environmental challenges through cutting-edge technology.…